About

Hi, I’m Jack!

I am a manufacturing engineer at Northrop Grumman. I graduated Summa Cum Laude from Cornell University with both an M.Eng. and B.S. in mechanical engineering. I am passionate about solving complex engineering challenges, driving innovative design, and contributing to meaningful technological advancements.

In 2023, I interned at Space Exploration Technologies Corp. (SpaceX) on the Raptor Engines Heat Shield Team. While I was based in Hawthorne, CA, I had several opportunities to travel to the launch site in Boca Chica, TX to contribute to the 9th iteration of Starship’s booster.

During my time at Cornell, I instructed students as a teaching assistant in two courses. The first covered topics ranging from CAD best practices to machining and fabrication. The second focused on understanding circuit components and combining them to create larger robotic assemblies.

Previously, I was the Structures Subteam Lead for Cornell Hyperloop where I was responsible for a number of projects including the development of a new aeroshell, integrating the electrical subteams’ hardware, and the implementation of a battery cooling system.

In the summer of 2022, I held a position at Sensata Technologies, Inc. as a mechanical engineering intern supporting the validation laboratory.

Please feel free to reach out via email at jack.stlouis@outlook.com or LinkedIn!

⇩

Engineering Experience

As a Manufacturing Engineer at Northrop Grumman, I author process plans, troubleshoot shop-floor issues, and implement ergonomic and efficiency improvements across three programs. One of my projects involves setting up an on-site facility for the final assembly of an electronic fuze. This has showcased my ability to develop process flows, design and implement a facility layout, and ensure compliance with safety and environmental regulations.

As an engineering intern on the Raptor Engines Heat Shield Team at SpaceX, I designed a thermal seal kit for Super Heavy’s 13 inner engines. Additionally, I analyzed and performed tests on flight-critical hardware under simulated in-flight conditions.

During my time at Cornell University, I taught courses including Mechanical Synthesis and Mechatronics. Mechanical Synthesis is one of the foundational courses in the major in which students learn to effectively utilize CAD software and operate machine shop equipment. Mechatronics teaches students how to use a variety of circuit components, and the underlying equations governing their behavior.

As a mechanical engineering intern at Sensata, I constructed a calibration station capable of supporting pressure sensors from three of Sensata’s product families, and integrated the system with a lab management software allowing global access to the station.

As the lead of Cornell Hyperloop’s Structures Subteam, I oversaw the design, analysis, prototyping, and fabrication of the hyperloop pod’s chassis and fuselage. I was also responsible for ensuring that components produced by other subteams were securely mounted to the chassis.

Projects

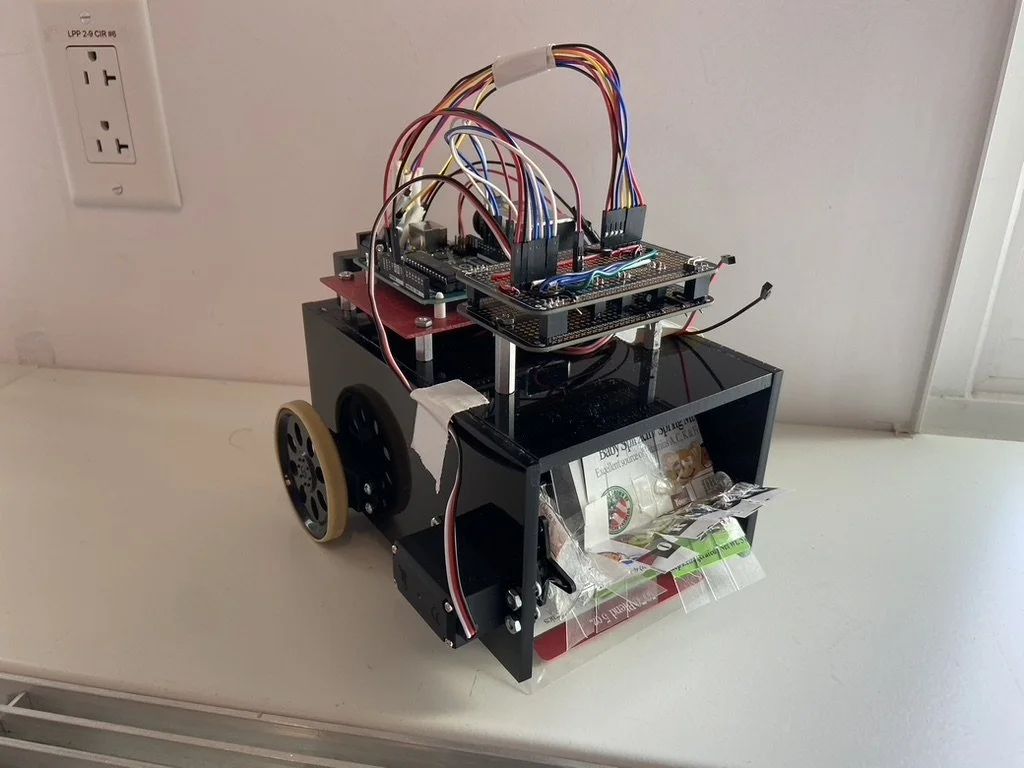

Cube Collecting Robot

This robot was designed to compete in a cube collecting competition. The goal was to move more cubes to your side of the board than your opponent. The robot placed in the top 4 of 52 teams.

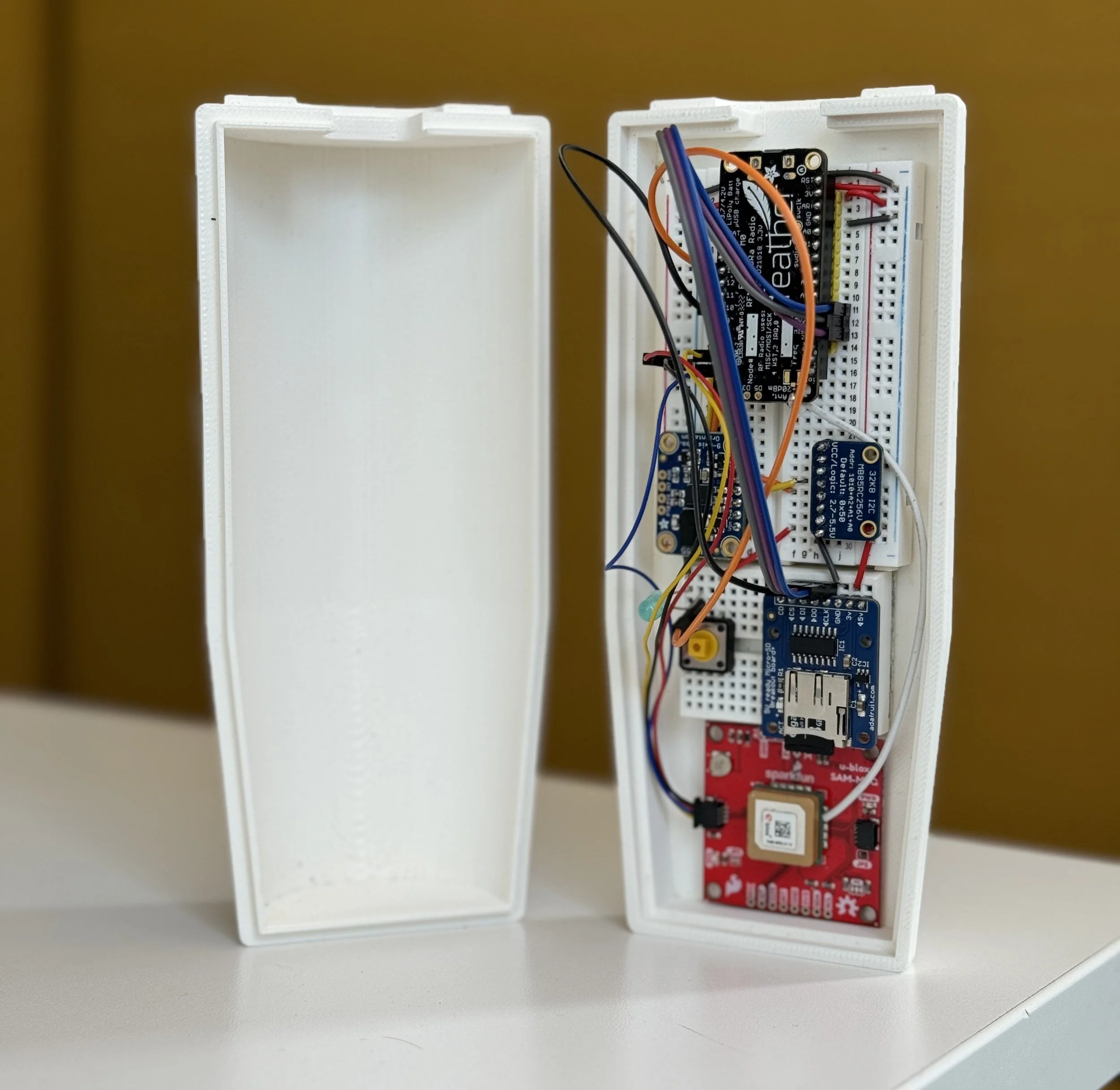

Pothole Detector

The goal of this project was to develop a module that detects potholes as a vehicle passes over them. This information can then be processed and passed on to local governments so that road repair resources can be allocated more efficiently.

Multi-Compartment Insulated Water Bottle

This bottle was designed as part of a product design class. The bottle features two thermally isolated chambers which allows the user to maintain two liquids at a distinct temperatures, such as ice water and coffee.

Turbine Blade Design

These turbine blade were made as part of a design challenge. The specifications of the wind tunnel were set, and the task was to create the most optimally efficient blade over a range of wind speeds.

Glider

This glider was made as part of an aeronautics course. The goal was to maximize the airtime of a flight spanning 15m or less. The glider ranked 2nd out of 22 teams.

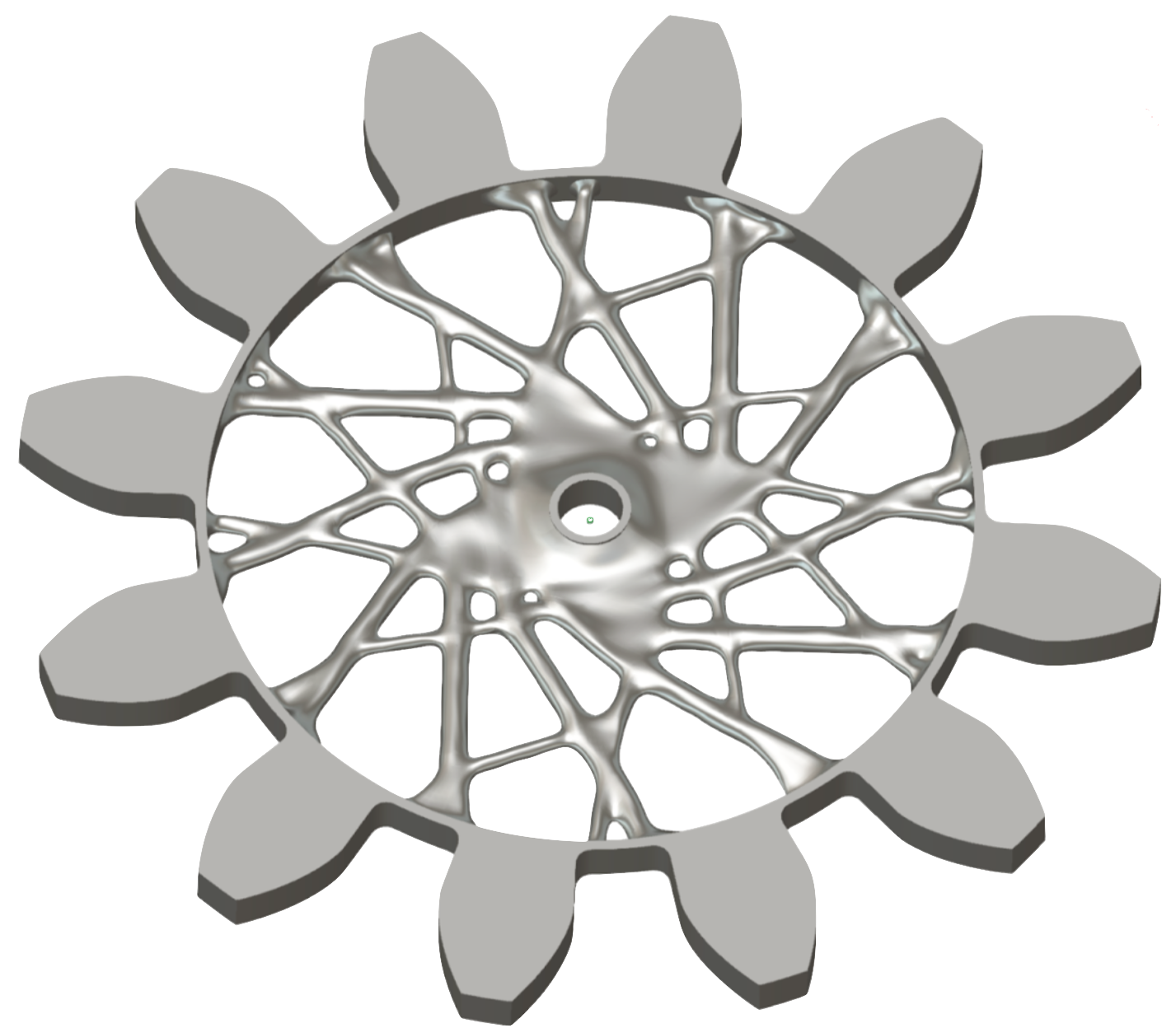

Generative Design Gear

Advancements in the fields of additive manufacturing and generative design have paved the way for a new generation of lighter, stronger parts. As part of this project, I minimized the weight of a gear utilizing generative design and topology optimization.